Introduction: PUF panels, short for Polyurethane Foam panels, are a versatile building material known for their excellent insulation properties and durability. These panels consist of an insulating core of Polyurethane Foam sandwiched between two outer layers, typically made of metal such as steel or aluminum. PUF panels find extensive use in various industries due to their thermal efficiency, lightweight nature, and ease of installation.

Scientific Name and Specifications: The scientific name for PUF panels is Polyurethane Foam panels. These panels come in different specifications, with variations in thickness, density, and outer layer material. Common thickness ranges include 30mm, 40mm, 50mm, up to 150mm or more. The density of the foam core can range from 35 kg/m³ to 45 kg/m³ or higher.

Uses and Applications: PUF panels have diverse applications across industries. In construction, they are used for roofing, wall cladding, and insulation in cold storage facilities, warehouses, commercial buildings, and residential structures. In the automotive industry, PUF panels are used for vehicle insulation. Additionally, they find use in temperature-controlled transportation, prefabricated structures, and modular buildings.

Materials Used: PUF panels consist of three main materials:

- Polyurethane Foam Core: This core material is responsible for providing outstanding thermal insulation properties, ensuring temperature regulation within structures.

- Outer Metal Layers (Steel or Aluminum): These layers serve as protective enclosures for the foam core, safeguarding it against external elements while also providing structural support.

- Adhesive: Used to firmly bond the foam core with the outer metal layers, ensuring a robust and durable construction.

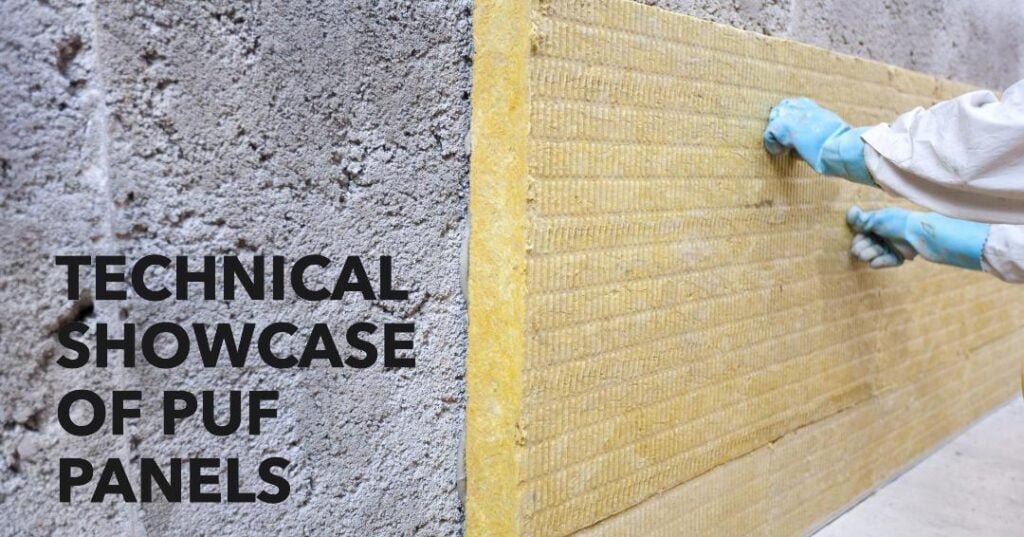

Installation: PUF panels are installed using various methods depending on the application. Common installation techniques include screwing, riveting, or bonding the panels to a structural framework.

Primary Usage Areas: PUF panels are primarily used in industries requiring temperature-controlled environments such as:

- Cold storage warehouses and food processing units

- Pharmaceutical storage facilities

- Refrigerated trucks and containers

- Clean rooms and laboratories

Reusability: While PUF panels are durable and long-lasting, their reusability depends on factors such as maintenance, handling, and environmental conditions. With proper care, PUF panels can be reused or recycled to some extent, contributing to sustainability efforts in construction and manufacturing.

Conclusion: PUF panels offer a cost-effective solution for thermal insulation and structural integrity across various industries. Their versatility, lightweight design, and thermal efficiency make them an indispensable component in modern construction and manufacturing processes. With ongoing advancements in materials and manufacturing techniques, PUF panels continue to play a vital role in sustainable building practices and energy-efficient infrastructure.